- Start date: 31/10/2023

- End date: 30/10/2026

- Coordinator: José Luis Sánchez

- Type: CET Partnership

- Funding: 189.000 €

The Project Consortium

● Abo Akademi University (coordinator), Finland

● KTH Royal Institute of Technology, Sweden

● University of Zaragoza, Spain

● Andritz Oy, Finland

● International Paper Inc., USA

● ValmetTechnologies Oy, Finland

● Valmet Ab, Sweden

Objectives

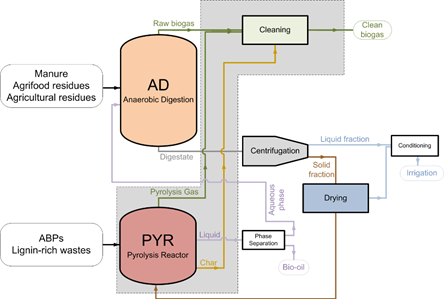

In the production of pulp, a pre-product for e.g. cardboard and paper, a by-product called black liquor (BL) is produced. The BL is utilized in Kraft recovery boilers (RB), which are multipurpose units, as they generate both electricity and heat, while recovering the pulping chemicals (Na and S). The RB is critical for the feasibility of the process. Yearly about 700 boilers burn around 220 million tonnes of BL, which is the largest biomass-based energy source in the world. This project aims to pave the road to the operation of Kraft recovery boilers in oxy-fuel mode. Oxy-combustion is a known technology to concentrate CO2 for further capture, however, applying oxy-combustion in Kraft recovery boilers has, so far, not been studied. The Kraft recovery boiler is an extremely complex device with the recovery of pulping chemicals as an essential part of the boiler design and operation. Oxy-combustion in Kraft recovery boilers would open opportunities for significant additional green energy production. In this project, we explore in detail the technical and economic feasibility of such a technology.

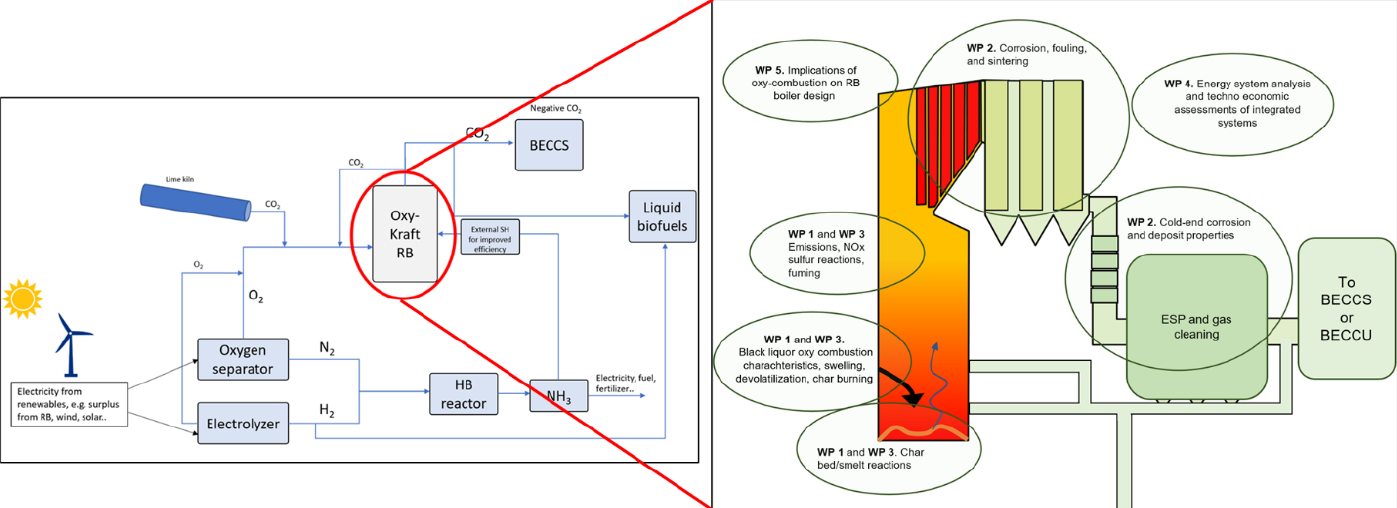

Challenges and approach beyond the state of the art

By changing the operation of a Kraft recovery boiler to oxy-fuel mode several processes will be affected in the boiler, e.g., to recover the chemicals in the right form, any changes in the chemical recovery process and the sulphur reduction in the bed have to be carefully studied. In addition, operational issues may change such as the liquor feed into the boiler. The liquor spray and the droplet size are of importance for the operation of the process to minimize fuming and carry over (escape of droplets and chemicals to the freeboard and further) and to keep a steady char bed at the boiler bottom. Changes in carry over and fume chemistry will induce changes in the heat exchanger corrosion behaviour, which directly mirrors back on the boiler availability and thus on the economy of the whole pulp mill. Further, the process changes can cause changes to critical gaseous emissions (NOx and SOx) that have to be controlled. A detailed understanding of the potential changes in these processes is crucial when devising new design and operation solutions for the novel Oxy-Kraft process.

Expected results and impact

An Oxy-Kraft recovery boiler would allow for the utilization of integrated green technologies, such as bioenergy with carbon capture and storage (BECCS) or bioenergy with carbon capture and use (BECCU), liquid biofuel production, green ammonia production in combination with the oxygen separation process, and smart/dynamic usage of the bioenergy depending on the energy market. The total fossil CO2 emissions in Finland are around 50 million tonnes. Consequently, capture and storage of all black liquor flue gas CO2 produced in Finland would compensate for a decrease of the total fossil CO2 emissions by about 35% (based on black liquor production and fossil CO2 in 2020) just with a single technology. An average-size recovery boiler in Finland burns 1.0 million tonnes of dry black liquor per year. Capturing the CO2 from ONE average Finnish recovery boiler (1.32 Mt CO2/year) equals roughly the emissions caused by 200 000 Finns (6.5 tonne/capita and year in 2020). This carbon capture would be, in fact, a net negative emission, as renewable carbon from biomass could be stored. This would greatly support the EU´s commitment to net-zero greenhouse gas emissions by 2050.

This project “Oxy-Kraft recovery boiler – Towards Novel Integrated Green Energy Parks” is part of the CET 2022 partnership-funded projects .

The CETPartnership is an initiative co-funded by the European Union that brings together public and private stakeholders in the research and innovation ecosystems, from European and non-European countries and regions. CET Partnership aims to create and foster transnational innovation ecosystems and overcome a fragmented research and innovation landscape.

The CET Partnership aims to empower the clean energy transition and contribute to the EU’s goal of becoming the first climate-neutral continent by 2050, by pooling national and regional RDTI funding for a broad variety of technologies and system solutions required to make the transition.

More info: https://blogs2.abo.fi/oxykraft/