- Start date: 01/01/2018

- End date: 30/09/2021

- Coordinator: Lucía García

- Type: Ministry of Economy, Industry and Competitivity

- Funding: 180.000 €

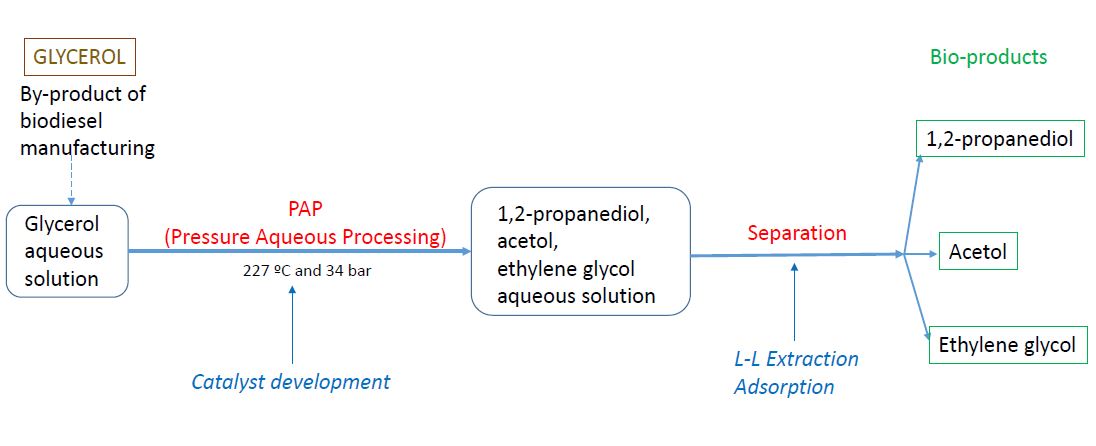

This project studies key aspects of the conversion of glycerol, a sub product in the process of producing biodiesel, to chemicals, including 1,2-propanediol, through Pressure Aqueous Processing (PAP). This process does not require the external supply of hydrogen, so it is a less costly and safer process than the conventional hydrogenolysis that requires hydrogen.

The overall objective of this project is to advance the knowledge of the glycerol PAP both at a scientific and technical level (catalyst, purity of food and separation of valuable products) and its economic viability in order to make viable the commercialization of the same. The catalyst plays a key role in the process. The combination of active metal, promoter and support in the catalyst, the method of preparation of the catalyst together with the conditions of operation decisively influence the conversion of the glycerol and product distribution. The catalyst and the most suitable method of preparation will be selected to achieve high conversion of the glycerol, high selectivity to 1,2-propanediol and stability under the reaction conditions. Catalysts will be prepared and characterized by various techniques. These catalysts will be experimentally tested in a laboratory scale facility with continuous feed of the aqueous chemical reactive glycerol solution. The catalysts will also be characterized after their use in the PAP to know and explain the causes of their possible loss of stability.